Welcome! Dongguan City - Casting Metal Products Co., Ltd

Dongguan Chengzhu Metal Products Co., Ltd.

Address: Minfu Street, Tanglip Village, Liaobu Town, Dongguan City, Guangdong Province

Telephone: 86-769-22654041

Passing true: 86-769-22654043

Website address: http://www.mag-alloy.com

Email: zhaochenghuang168@163.com

Chengxintong Enterprise: zch13825787603

Business QQ: 425090969

Mobile: 13825787603

Established in early 2006, Dongguan Chengzhao Metal Products Co., Ltd. is located in Dongguan City, Guangdong Province, China. It is a comprehensive processing company specializing in the production, manufacture and sales of magnesium alloy and aluminum alloy. It has passed ISO9001: 2008 International Quality System Certification. Since its inception, has been focused on magnesium alloy and aluminum alloy components design and manufacturing, mainly related products include: magnesium alloy die casting, aluminum die casting......

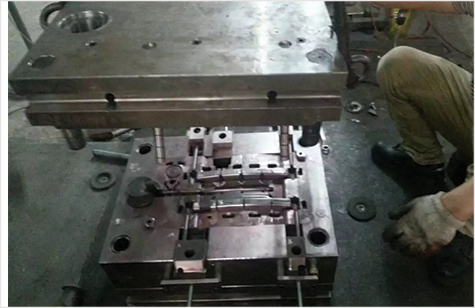

The main products involved include: magnesium alloy die castings, precision magnesium alloy die casting dies, electric vehicle parts die casting, sports equipment die casting, camera die casting, photo tripod die casting, laser projector die casting, vehicle die casting, mechanical product die casting, medical equipment die casting , And other products.

Microphone (crimping block) -21

Cavity Die Castings-23

Communications Accessories — 17

Communication products-06

Aluminum cavity-24

⑴.The company is strong and experienced:

More than 10 years of precision machining design experience, fast production speed, short supply cycle, one-stop service, fully automated flow production mode, independent die casting workshop, post-processing workshop, mold room, testing equipment workshop.

⑵.Introduce German production technology and Japanese enterprise production management standards:

Advanced imported casting equipment, testing equipment and reliable quality castings and casting materials. The yield rate is 99%. The company has passed ISO9001-2008 quality system certification. Meet ZBGB national industry standards.

⑶.With unique core technology, more competitive:

Professional die-casting mold flow analysis software and 3D mold design. Introduced cutting-edge mold making and mold surface treatment technology. High-precision alloy die-casting parts.

⑷.Excellent service and worry-free throughout:

Free mold design fee for the first cooperation, samples can be produced as soon as 20 days

Product quality and production problems, 2 hours response measures, settlement within 1 day

Adopt early warning method, scientifically control production progress, 100% delivery on time