Company technical parameters

Release time:

2024-11-28 11:53

Source:

Please directly install the product information (3D/2D) and requirements to inform:

a. Processed materials (magnesium alloy (AZ91D AM60B, etc.) aluminum alloy (ADC12ADC10 A356.2 DM5, etc.))

B. Production and processing quantity

d. Whether heat treatment and surface treatment are required

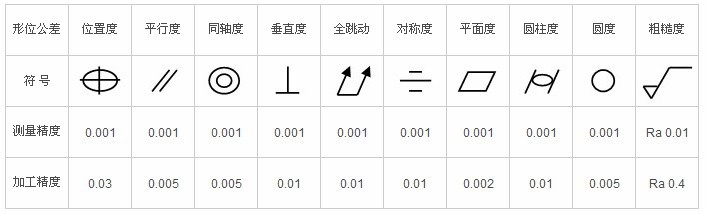

e. Machining accuracy

F. if the parents think the price of our store is too high, it will be more affordable there. if they do a lot of details, they don't know. I don't want to explain too much. it is better to print the drawings on a white background for me (please indicate if you have any other requirements)

G please send the drawings to our E-mailzhaochunghuang168@163.comOr QQ(1497063213/425090969) online contact, we will quote the price to you as soon as possible.

Matters needing attention in processing:

1. Our factory will use your most satisfactory express delivery in terms of express delivery. Please tell me in advance (freight customers pay their own expenses) or the buyer will specify;

2. Generally, the tolerance requirements shall be indicated in the drawings. Those who need special attention can call (13825787603);

3. Regarding the delivery date, due to occasional unforeseen circumstances, our factory cannot guarantee 100% delivery at the agreed time, but we will do our best to complete it in advance or within the agreed time.

4. Our factory needs to provide drawings for processing. Before making an inquiry, please prepare the drawings (the drawing format can be 2D or 3D). Please note the tolerance range. The unnoted tolerances are plus or minus 0.1mm. Parts with mutual matching relationship need special declaration;

5. Custom processing, single piece and small batch parts processing, (customers develop CAD,PDF,stp and pro/e drawings for quotation, please indicate whether tax is included in the quotation, and the company can make out an invoice.)

6. The factory refused to process and discuss the parts in conflict with national laws

Product details parameters:

| Type of processing service |

Welcome to map, sample processing, or in accordance with the requirements of the guests design, production and production |

| die casting machine tonnage |

180T-1200T |

| Die casting process |

Die casting → denozzle → deburring → grinding → drilling → tapping → CNC finishing → surface treatment → QC inspection → packaging |

| Surface treatment |

Anodized oil spray powder spray paint electrophoresis film chemical sandblasting, etc., can also be according to customer requirements |

| Material |

Magnesium alloy: AZ91DAM60B and other aluminum alloy: ADC12ADC10 A356.2 DM5 and so on |

| Weight |

0.1-10KG |

| Ideas |

Ensure quality innovation and refinement |

| Certificate |

ISO9001:2008 international quality system certification |

Description by case:

Previous Page

Related News

Analysis of Common Problems in High-end Robot Castings

High-end robot castings play an important role in modern industrial production, but there are also some common problems in the use process, which affect production efficiency and quality. This article will analyze the common problems and solutions of high-end robot castings to help readers better deal with these challenges.

High-end robot casting industry program

The high-end robot casting industry is developing towards automation and intelligence, and strives to improve production efficiency and ensure product quality. This article will discuss the development trend and industry plan of high-end robot castings.

High-end robot casting working principle

High-end robot castings are a key part of modern manufacturing, and their working principles involve advanced technology and precise manufacturing processes.

High-end robot castings to innovate the future of science and technology

As an important part of modern science and technology, high-end robot castings play a key role. Its meticulous craftsmanship and high-quality materials provide reliable support for the robotics industry and promote the continuous development of science and technology.

High-end robot castings refer to parts produced using advanced technology in the manufacturing process. They are widely used in the field of robot manufacturing and have the characteristics of high precision and wear resistance.

Magnesium alloy die casting detailed description

Light weight, low density, 63% of aluminum alloy, 25% of iron.