Dongguan Chengzhu Metal Products Co., Ltd.

Address: Fujie, Tanglip Villager, Liaobu Town, Dongguan City, Guangdong Province

Telephone:86-769-22654041

Fax: 86-769-22654043

Website:http://www.mag-alloy.com

Email:zhaochenghuang168@163.com

Integrity of the enterprise: zch13825787603

Business QQ:425090969

Mobile:+86 13825787603

Company Profile

Dongguan Chengzhu Metal Products Co., Ltd. is located in Dongguan, Guangdong, a famous manufacturing city in China. It was established in early 2006. It is a comprehensive processing products company specializing in the production, manufacturing and sales of magnesium alloys. It has passed the ISO9001:2008 international quality system certification.

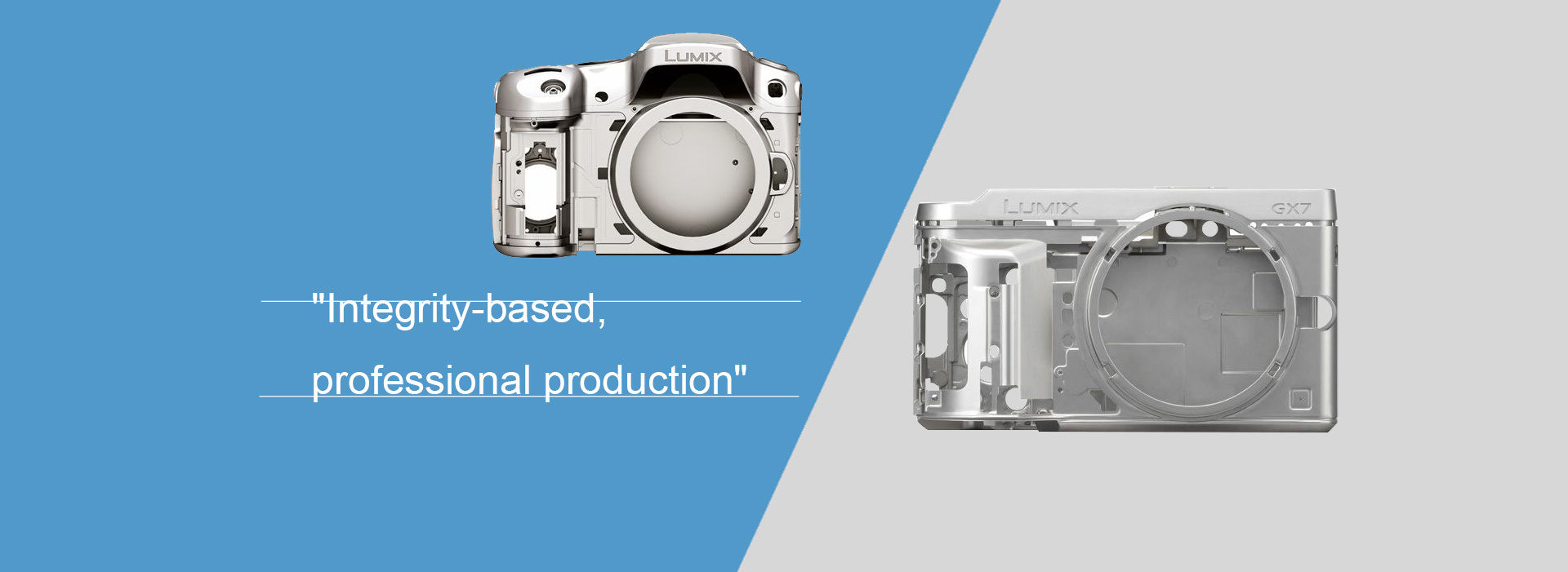

Since its establishment, it has been focusing on the design and manufacture of magnesium alloy and aluminum alloy components, mainly involving products including: magnesium alloy die-casting parts, precision magnesium alloy die-casting molds, electric vehicle accessories die-casting, LED lighting die-casting, sports equipment die-casting, camera die-casting, photography tripod die-casting, laser projector die-casting, vehicle die-casting, mechanical products die-casting, medical equipment die-casting, security products die-casting and other series of products.

The company covers an area of 10000 square meters and has its own mold room. At present, the number of employees is nearly 150, including mold design, mold technicians, die-casting technicians and other professional and technical personnel. After several years of development, the company has a full set of production, post-processing, Testing equipment, etc, there are hot chamber die casting machine, cold chamber die casting machine, precision machining, hydraulic trimming machine, desktop tapping machine, gear pitch automatic tapping machine, precision milling machine, precision grinding machine, polishing motor, precision spark machine, salt spray machine, measuring instruments and other supporting equipment.

We mainly carry out hardware processing, manufacturing, mold opening, proofing and production according to customers' drawings and samples. We have mature production technology and rich professional and technical personnel. From the moment of mold opening to the product on-line and off-line, our masters are measuring and monitoring the accuracy and stability of the product.

We firmly believe that the various specifications of products produced by the company meet the needs of customers. The company has always been "customer-oriented, service-first" tenet, and sincerely provide customers with high-quality products and high-quality services!

Our core competencies

● Built in Dongguan, Guangdong in early 2006, with many years of experience in die casting production

● Has a complete manufacturing process, including mold design and manufacturing, die casting, machining, electroplating, paint, anodizing, powder spraying, electrophoresis, sandblasting and other surface treatment

● High mobility of mold manufacturing and maintenance capabilities

● Product development capabilities in sync with global customers

● Have a variety of capacity to meet mass production needs

● Capacity of large and small tonnage of die casting machine equipment

● A full set of central vacuum die casting equipment can optimize the quality of die castings

● Test equipment can guarantee various quality requirements of customers

R & D Mould Department

Mold plays a very important part in the production and manufacturing, provide timely mold maintenance and maintenance to ensure normal production operation, and cooperate with different die casting machines

Production, so that it reaches the best condition.

Die casting equipment

· Magnesium alloy die casting machine

· Magnesium alloy die casting equipment

precision machining

The company can provide a full range of one-stop services, including die-casting, trimming, deburring, drilling, tapping, milling, turning, vibration grinding, polishing, powder baking paint, liquid baking paint and assembly.

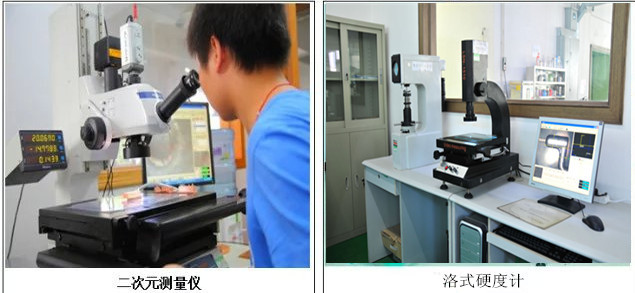

Testing equipment

We have imported testing equipment from Germany and Italy, including spectrometers, three-dimensional, optical projectors, etc. These equipment can strictly control and ensure the product quality in each production process.