Dongguan Chengzhu Metal Products Co., Ltd.

Address: Fujie, Tanglip Villager, Liaobu Town, Dongguan City, Guangdong Province

Telephone:86-769-22654041

Fax: 86-769-22654043

Website:http://www.mag-alloy.com

Email:zhaochenghuang168@163.com

Integrity of the enterprise: zch13825787603

Business QQ:425090969

Mobile:+86 13825787603

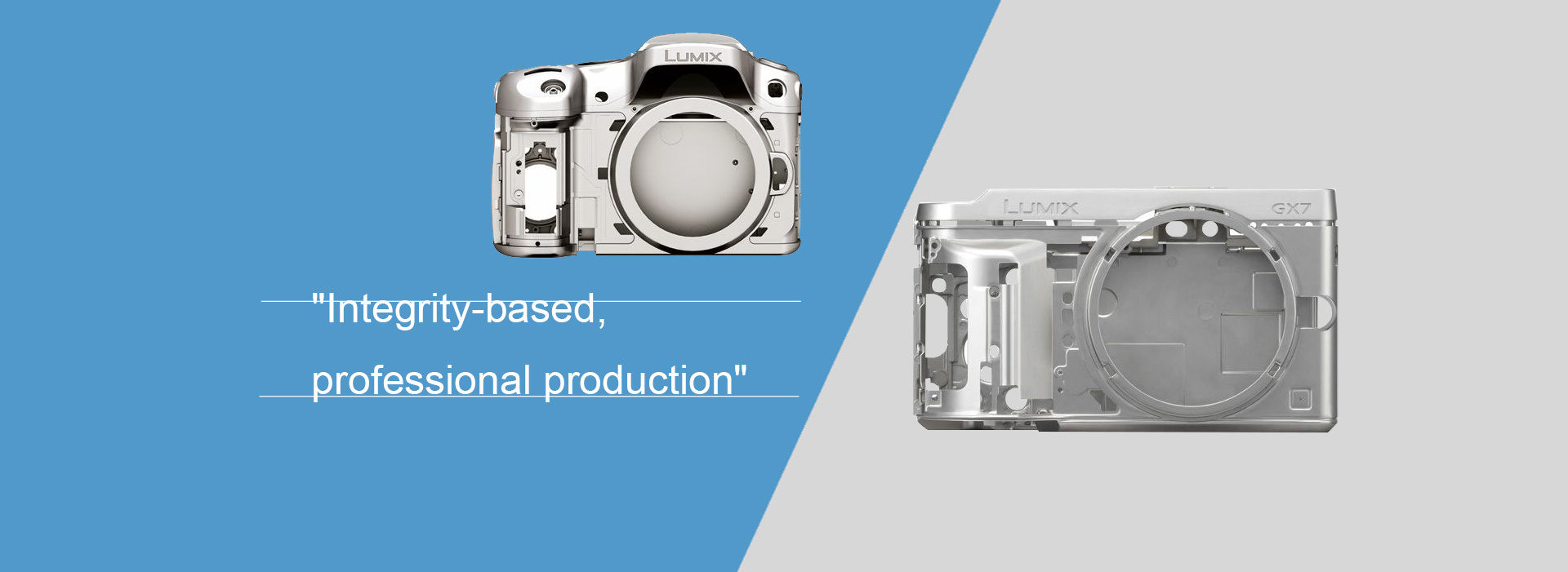

Magnesium alloy die casting detailed description

1. Features:

★Light weight, low density, 63% of aluminum alloy, 25% of iron.

★Specific strength and specific stiffness are better than aluminum alloy and steel.

★High vibration absorption and noise reduction.

★It has good electromagnetic wave shielding performance.

★Dimensional temperature qualitative high.

★Good heat dissipation

★Die casting performance is good, the minimum wall thickness of castings can reach 0.5MM.

2. Purpose:

★Automotive industry steering wheel, instrument panel, wheel hub, clutch housing, etc.

★3C industry mobile phone, notebook computer, digital camera and other shell.

★Aerospace aircraft wings, rocket shells, artificial satellites, spacecraft structural parts.

★Other industries power tools, bicycles, suitcases, torches, etc.

3. Compared with magnesium alloy die casting and aluminum alloy die casting:

★Productivity is 50% higher.

★Steel molds can be used to extend service life.

★Lower latent heat, saving energy.

★Good machinability.

★Mold cost savings of 50%.

★The melt has a higher fluidity.

4. Types and applications of magnesium alloys:

◆ AZ91: With good casting performance and strength, it is used for complex-shaped thin-walled parts, such as automobiles, computer parts, hand tools, sports appliances, and household appliances.

◆ AM50, AM60: It has outstanding toughness and energy absorption, and has good strength and mechanical properties. It is used in car seats, steering wheels, dashboards, and car wheels.

AM20: High toughness and impact strength, used for parts requiring high toughness.

AS41: good creep resistance at 150 degrees, used to withstand high load parts, such as cylinder block.

★Good cutting performance.

★The appearance and touch texture of magnesium alloy is excellent, making the product more luxurious.

★Recyclable, green environmental protection.

★The reserves of magnesium in the earth's crust rank eighth, and most of the magnesium raw materials are extracted from seawater, so its resources are stable and sufficient.

Common Terms for Magnesium Alloy Die Casting Process

压铸(die casting)

铜丝刷磨面(brushed surface by brass brush wheels)

QC巡检(QC tour-inspection)

Shearing nozzle (degating)

冲内窗口(internal frame trimming)

磨四边批锋(removing flash around external frame)

刮顶针批锋(removing burrs round pads of ejector pin)

File the four sides of the inner window (filing internal frame)

内窗四边磨砂纸(abrading internal frame by abrasive paper)

刮四按钮孔(removing burrs in 4 button holes)

全检(full-inspection)

Drilling (drilling)

Tapping (tapping)

钝化(passivating)

喷油前全检(full-inspection prior to painting)

Wiping with toluene

背面喷面油(applying top coat to bottom surface)

表面喷底油(applying primer coat to top surface)

Baking

表面喷面油(applying top coat to top surface)

移印/丝印(PAD printing/silk screening)

抽检(sampling inspection)

全检(full-inspection)

Packaging (packaging)